Engineering, 13.02.2022 05:10, CassidgTab

For these problems I feel like I am close but i don't quite fully understand them yet.

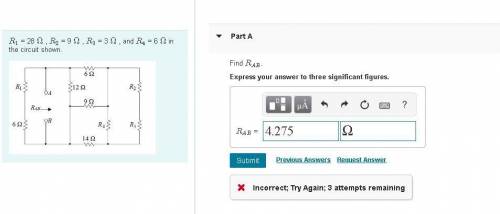

For calculating R_AB, I am not sure how the A and B terminals affect the whole circuit. Ive calculated the resistance of the circuit as a whole as if terminals A and B were not even there and calculated the resistance as if the resistances were in parallel from node A and node B. But i still get the wrong answer.

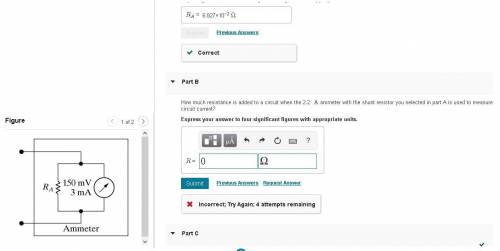

For the second question when calculating the solution for part B, I am also not sure how to calculate the resistance added by the ammeter. I know how to calculate the resistance of the shunt resistor though, how do i calculate how much resistance was added to the circuit. I calculate 50 ohms every time by dividing 150mV by 3mA.

Any help and direction is greatly appreciated

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, lillygrl100

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:10, redrosesxx

Water at 55c flows across a flat plate whose surface temperature is held constant at 95c. if the temperature gradient at the plate's surface for a given value of x is 18 c/mm, find a) local heat transfer coefficient. b) heat flux

Answers: 3

Engineering, 04.07.2019 18:10, dval1146

You are making beer. the first step is filling the glass carboy with the liquid wort. the internal diameter of the carboy is 15 in., and you wish to fill it up to a depth of 2 ft. if your wort is drawn from the kettle using a siphon process that flows at 3 gpm, how long will it take to fill?

Answers: 1

Engineering, 04.07.2019 18:10, demarcuswiseman

Calculate the bore of a cylinder that has a stroke of 18 inches and an extension time of 6 seconds at a flow rate of 4 gal/min.

Answers: 3

Do you know the correct answer?

For these problems I feel like I am close but i don't quite fully understand them yet.

For calcula...

Questions in other subjects:

English, 04.02.2021 17:20

Mathematics, 04.02.2021 17:20

Business, 04.02.2021 17:20

Mathematics, 04.02.2021 17:20