Engineering, 18.03.2021 01:20, Lacey9319

A completely mixed high rate-activated sludge plant with recycletreats 17,500 m3/day of industrial wastewater. The influent to theactivated sludge reactor has a BOD5 of 1000 mg/L. It is desired toreduce the influent BOD5 to 120 mg/L, prior to discharge to a municipalsewer. Pilot plant analysis gave the following results: mean cellresidence time = 6 d, MLSS concentration in reactor = 5500 mg/L, Y = 0.6 kg/kg, kd = 0.03 d–1. Determine the following:.

a. The hydraulic retention time and volume of the activated sludge

b. The wolumetric loading rate in kg BOD,/m- day to the reactor.

c. The F/M ratio in the reactor

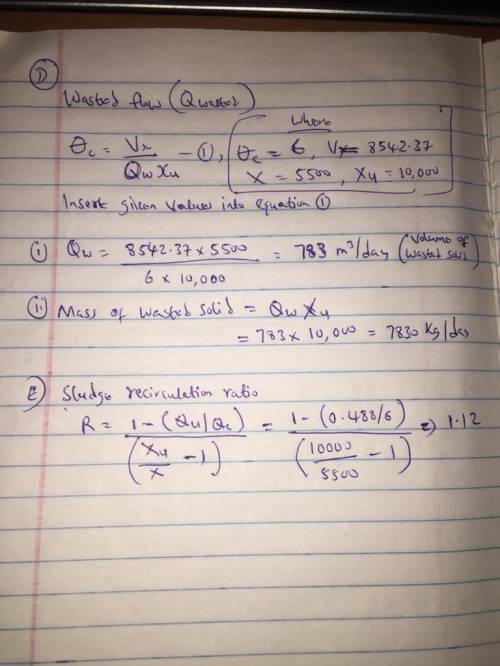

The mass and valume of solids wasted each day, at an underflow solids concentration, Xu = 10,000 mg/L.

e. The sludge recirculation ratio

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, danksans7011

The mass flow rate of the fluid remains constant in all steady flow process. a)- true b)- false

Answers: 1

Engineering, 04.07.2019 18:10, lillygrl100

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:20, cxttiemsp021

Atank with constant volume contains 2.27 kg of a mixture of water phases (liquid-vapor). in the initial state the temperature and the quality are 127 °c and 0.6, respectively. the mixture is heated until the temperature of 160 oc is reached. illustrate the process in a t-v diagram. then, determine (1) the mass of the vapor in kg at the initial state, (2) the final pressure in kpa.

Answers: 3

Engineering, 06.07.2019 03:20, lelen2021

Steam at a pressure of 100 kpa and a quality of 50% initially fills a rigid vessel having a volume of 0.5 m^3. the steam is then heated, causing the pressure in the vessel to rise to 150 kpa. determine: i. the mass of the steam in the vessel. ii. the temperature and quality of the steam after the heating process. ii the mass of the vapour, mg and liquid, m in the vessel after the heating process. if the steam in the vessel is now further heated, what would the pressure and temperature in the vessel be when all steam has turned into saturated vapour? b. sketch the processes in part (a) and part (b) on p-v and t-v diagrams, indicating clearly the temperatures, pressures and the paths. c. (0.59kg, 111.4°c, 73%, 0.4307kg, 0.1 593kg, 2.11 bar, 121.84°c)

Answers: 1

Do you know the correct answer?

A completely mixed high rate-activated sludge plant with recycletreats 17,500 m3/day of industrial w...

Questions in other subjects:

History, 20.01.2021 02:20

Mathematics, 20.01.2021 02:20

. therefore OH = 0.488 days ≈ 11.72 hour

. therefore OH = 0.488 days ≈ 11.72 hour