Engineering, 18.11.2020 17:10, kylee76

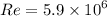

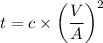

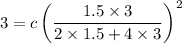

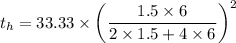

Pure aluminum is poured into a sand mold. The metal level in the pouring basin is 10 in. above the metal level in the mold, and the runner is circular with a 0.4-in. diameter. What are the velocity and rate of the flow of the metal into the mold? Is the flow turbulent or laminar? 10.44 A cylinder with a diameter of 1.5 in. and height of 3 in. solidifies in 3 minutes in a sand casting operation. What is the solidification time if the cylinder height is doubled? What is the time if the diameter is doubled?

Answers: 1

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, jojoangelique13

The flow rate of air through a through a pipe is 0.02 m5/s. a pitot static tube is placed in the flow. the radius of the pitot static tube is 1 mm. assuming the flow to be steady and the air to be at 300k, calculate the difference in total and static pressure if the diameter of the pipe is: (a) d 0.1 m d 0.05 m (c) d 0.01 m

Answers: 2

Engineering, 04.07.2019 18:20, samantha636

Avolume of 2.65 m3 of air in a rigid, insulated container fitted with a paddle wheel is initially at 264 k, 5.6 bar. the air receives 432 kj by work from the paddle wheel. assuming the ideal gas model with cv = 0.71 kj/kg • k, determine for the air the amount of entropy produced, in kj/k

Answers: 2

Engineering, 04.07.2019 18:20, maciemarklin79981

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

Engineering, 04.07.2019 18:20, Doogsterr

For each of the following process: a) sketch the p-v diagram, b)sketch t-s diagram, c) sketch t-v diagram, d) sketch the boundary work on one of the diagrams (a, b or c) and e) sketch the reversible heat transfer on one of the diagrams (a, b or c): 1- isobaric process from compressed liquid to superheated vapor 2- isothermal process from compressed liquid to superheated vapor 3- isentropic process from compressed liquid to superheated vapor

Answers: 3

Do you know the correct answer?

Pure aluminum is poured into a sand mold. The metal level in the pouring basin is 10 in. above the m...

Questions in other subjects:

English, 06.07.2019 18:00

Mathematics, 06.07.2019 18:00

Biology, 06.07.2019 18:00

Computers and Technology, 06.07.2019 18:00

Mathematics, 06.07.2019 18:00

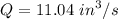

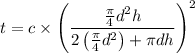

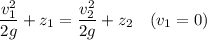

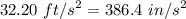

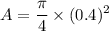

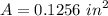

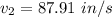

for g and 10 in for Δz in velocity equation,

for g and 10 in for Δz in velocity equation,

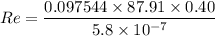

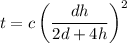

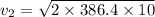

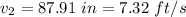

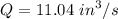

and the flow rate is

and the flow rate is