Engineering, 29.05.2020 21:57, noahwhitfield5331

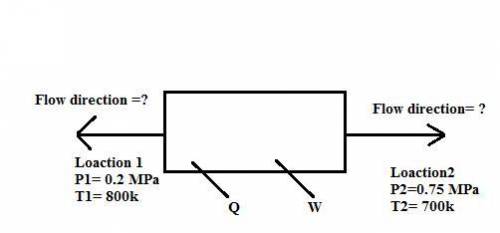

Problem Statement: Air flows at a rate of 0.1 kg/s through a device as shown below. The pressure and temperature of the air at location 1 are 0.2 MPa and 800 K and at location 2 the pressure and temperature are 0.75 MPa and 700 K. The surroundings are at 300 K and the surface temperature of the device is 1000 K. Determine the rate that the device performs work on its surroundings if the rate of heat transfer from the surface of the device to the environment is 1 kW. Justify your answer. Note that the flow direction for the air is not specified so you need to consider all possibilities for the direction of the airflow. Assume that the air is an ideal gas, that R

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, lillygrl100

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:10, Larkinlover703

Items are similar to the free issue items, but their access is limited. (clo5) a)-bin stock items free issue b)-bin stock controlled issue c)-critical or insurance spares d)-rebuildable spares e)-consumables

Answers: 1

Engineering, 04.07.2019 18:10, krystabrewer3

What are the two (02) benefits, which may result from a successful implementation of preventive maintenance (pm) program in an organization? (clo3)a)- lean manufacturing b)-overlapping responsibilities c)-the planner is not qualified d)-accurate contractor information e)-reduction in equipment redundancies f)-accurate stores information

Answers: 3

Engineering, 04.07.2019 18:10, 0436500

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

Do you know the correct answer?

Problem Statement: Air flows at a rate of 0.1 kg/s through a device as shown below. The pressure and...

Questions in other subjects:

English, 04.10.2019 20:00

Geography, 04.10.2019 20:00

Mathematics, 04.10.2019 20:00

Mathematics, 04.10.2019 20:00

History, 04.10.2019 20:00

![m\{n_1+ \frac{v^2_1}{z}+ gz_1 \}+Q= m \{h_2+ \frac{v^2_2}{2}+ gz_2\}+w\\\\\ change \ energy\\\\0.1[1.005 \times 800]-1= 0.01[1.005\times 700]+w\\\\w= +9.05 \ kw\\\\](/tpl/images/0670/7234/5ea40.png)