Engineering, 22.04.2020 04:51, carsondelane13

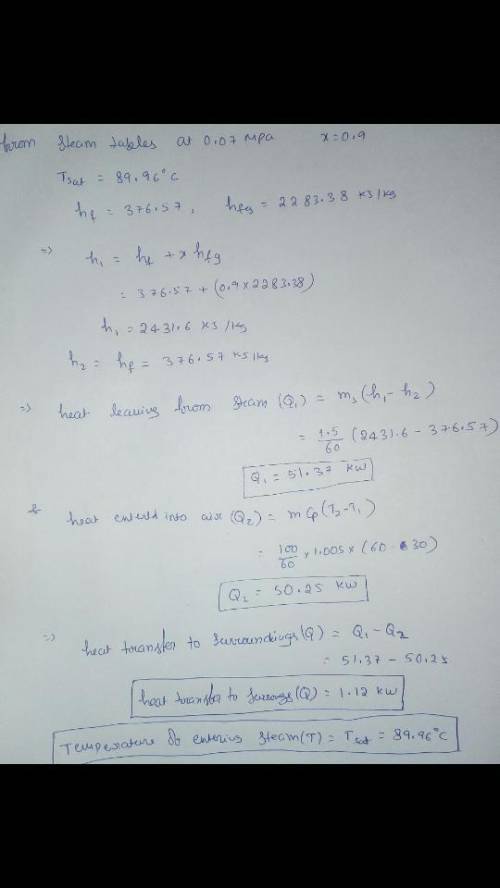

Steam enters a counterflow heat exchanger operating at steady state at 0.07 MPa with a quality of 0.9 and exits at the same pressure as saturated liquid. The steam mass flow rate is 1.5 kg/min. A separate stream of air with a mass flow rate of 100 kg/min enters at 30°C and exits at 60°C. The ideal gas model with 1.005 kJ/kg · K can be assumed for air. Kinetic and potential energy effects are negligible. Determine the temperature of the entering steam, in °C, and for the overall heat exchanger as the control volume, what is the rate of heat transfer, in kW.

Answers: 3

Other questions on the subject: Engineering

Engineering, 03.07.2019 15:10, theamandawhite

Ahouse has the following electrical appliance usage (1) single 40w lamp used for 4 hours per day (2) single 60w fan used for 12 hours per day (3) single 200w refrigerator that runs 24 hours per day with compressor run 12 hours and off 12 hours find the solar power inverter size in watt with correction factor of 1.25.

Answers: 1

Engineering, 04.07.2019 18:10, selenamr

Ifa component is made of two or more materials with different modulus of elasticity (e), it is called a composite member and we calculate the factor·n". mention the formula for calculating n". also, ifn> 1, explain what will happen to the 1. transformed. gi) ifn 1, what will happen to the material when transformed material when

Answers: 1

Engineering, 04.07.2019 18:20, maciemarklin79981

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

Engineering, 04.07.2019 18:20, Doogsterr

For each of the following process: a) sketch the p-v diagram, b)sketch t-s diagram, c) sketch t-v diagram, d) sketch the boundary work on one of the diagrams (a, b or c) and e) sketch the reversible heat transfer on one of the diagrams (a, b or c): 1- isobaric process from compressed liquid to superheated vapor 2- isothermal process from compressed liquid to superheated vapor 3- isentropic process from compressed liquid to superheated vapor

Answers: 3

Do you know the correct answer?

Steam enters a counterflow heat exchanger operating at steady state at 0.07 MPa with a quality of 0....

Questions in other subjects:

Chemistry, 25.02.2021 22:30

Mathematics, 25.02.2021 22:30

History, 25.02.2021 22:30