Engineering, 11.04.2020 04:03, chris159128

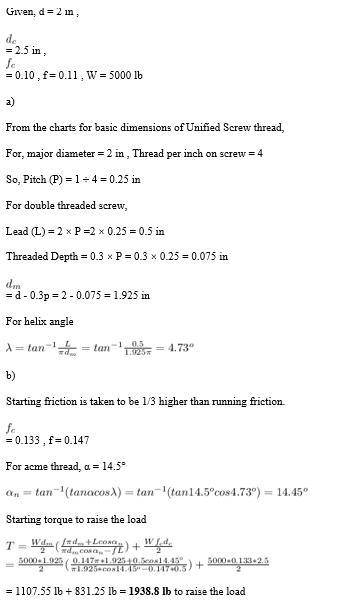

A double threaded Acme stub screw of 2-inch major diameter is used in a jack having a plain thrust collar of 2.5

inch mean diameter. Coefficients of running friction are estimated as 0.10 for the collar and 0.11 for the screw.

(a) Determine the pitch, lead, thread depth, mean pitch diameter, and helix angle of the screw.

(b) Estimate the starting torque for raising and for lowering a 5000 lb load.

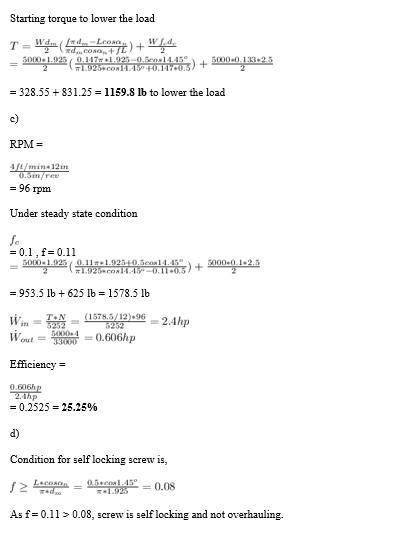

(c) If the screw is lifting a 5000 lb load at the rate of 4 ft/min, what is the screw rpm? What is the efficiency of the jack under this steady-state condition?

(d)Would the screw overhaul if a ball thrust bearing (of negligible friction) were used in place of the plain thrust collar.

Answers: 1

Other questions on the subject: Engineering

Engineering, 03.07.2019 14:10, aliceohern

The y form of iron is known as: a) ferrite b) cementite c) perlite d) austenite

Answers: 3

Engineering, 04.07.2019 18:10, lillygrl100

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:20, yasyyas646646

Agas mixture consists of 8 kmol of h2 and 2 kmol of n2. determine the mass of each gas and the apparent gas constant of the mixture.

Answers: 3

Engineering, 04.07.2019 19:20, kaitlyn114433

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

Do you know the correct answer?

A double threaded Acme stub screw of 2-inch major diameter is used in a jack having a plain thrust c...

Questions in other subjects:

History, 19.07.2019 08:40

Mathematics, 19.07.2019 08:40

Chemistry, 19.07.2019 08:40

Business, 19.07.2019 08:40

History, 19.07.2019 08:40

Physics, 19.07.2019 08:40