Engineering, 07.04.2020 00:17, angelina6836

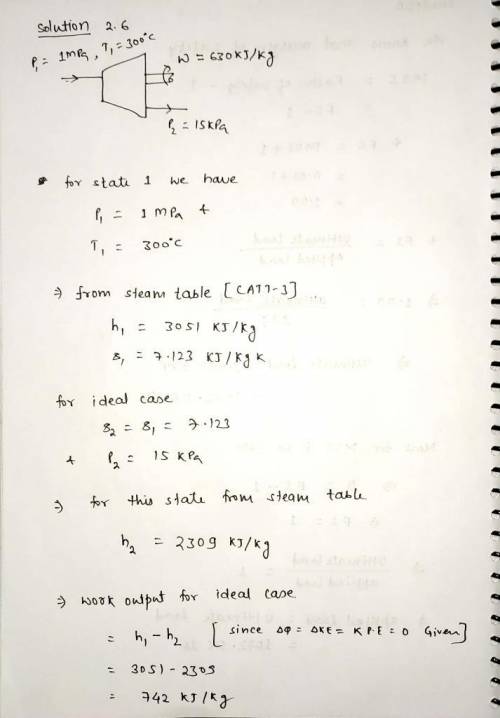

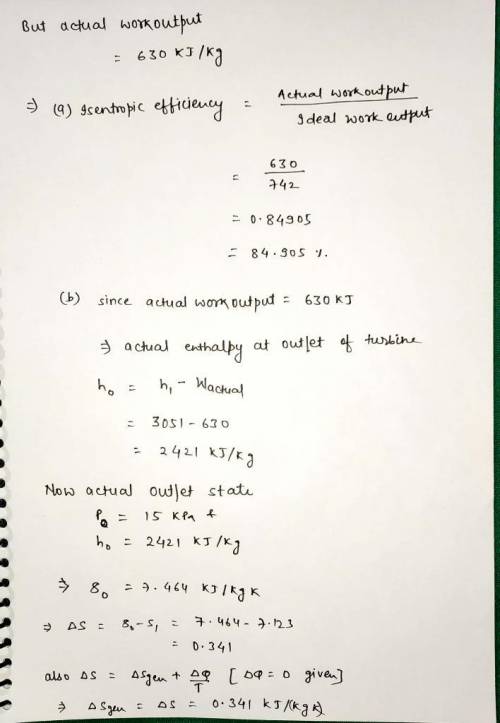

Water vapor at 1.0 MPa, 300°C enters a turbine operating at steady state and expands to 15 kPa. The work developed by the turbine is 630 kJ per kg of steam flowing through the turbine. Ignoring heat transfer with the surroundings and kinetic and potential energy effects, deter- mine (a) the isentropic turbine efficiency, (b) the rate of entropy gen- eration, in kJ/K per kg of steam flowing. Air at 40°F, 1 atm enters a compressor operating at steady state and exits at 620°F, 8.6 atm. Ignoring heat transfer with the surroundings and kinetic and potential energy effects, determine (a) the isentro- pic compressor efficiency and (b) the rate of entropy generation, in Btu/ºr per lb of air flowing. 2.7

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, viicborella

Steel is coated with a thin layer of ceramic to protect against corrosion. what do you expect to happen to the coating when the temperature of the steel is increased significantly? explain.

Answers: 1

Engineering, 04.07.2019 18:10, heidiburgos1own6c0

Fluids at rest possess no flow energy. a)- true b)- false

Answers: 3

Engineering, 04.07.2019 18:10, abdirahmansoloman

Air is to be cooled in the evaporator section of a refrigerator by passing it over a bank of 0.8-cm-outer-diameter and 0.4-m-long tubes inside which the refrigerant is evaporating at -20°c. air approaches the tube bank in the normal direction at 0°c and 1 atm with a mean velocity of 4 m/s. the tubes are arranged in-line with longitudinal and transverse pitches of sl- st 1.5 cm. there are 30 rows in the flow direction with 15 tubes in each row. determine (a) the refrigeration capacity of this system and (b) pressure drop across the tube bank. evaluate the air properties at an assumed mean temperature of -5°c and 1 atm. is this a good assumption?

Answers: 1

Engineering, 04.07.2019 18:10, 0436500

Aturning operation is performed with following conditions: rake angle of 12°, a feed of 0.35 mm/rev, and a depth of cut of 1.1 mm. the work piece is aluminum alloy 6061 with t6 heat treatment (a16061-t6). the resultant chip thickness was measured to be 1.0 mm. estimate the cutting force, fc. use shear stress of 207 mpa and coefficient of friction on the tool face of 0.6.

Answers: 1

Do you know the correct answer?

Water vapor at 1.0 MPa, 300°C enters a turbine operating at steady state and expands to 15 kPa. The...

Questions in other subjects:

Arts, 23.03.2021 18:30

History, 23.03.2021 18:30

English, 23.03.2021 18:30

Mathematics, 23.03.2021 18:30

Social Studies, 23.03.2021 18:30

Computers and Technology, 23.03.2021 18:30