Engineering, 31.03.2020 00:55, peno211

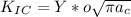

A structural component in the shape of a flat plate 25.0 mm thick is to be fabricated from a metal alloy for which the yield strength and plane strain fracture toughness values are 545 MPa and 29.6 MPa-m1/2, respectively. For this particular geometry, the value of Y is 1.3. Assuming a design stress of 0.3 times the yield strength, calculate the critical length of a surface flaw.

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 08:10, doggo242

Which of the following is an easy way to remember the modified “x” tire rotation? a. nondrive wheels straight, cross the drive wheels b. drive wheels straight, cross the nondrive wheels c. drive wheels crossed, nondrive wheels straight d. drive wheels crossed, nondrive wheels crossed

Answers: 1

Engineering, 04.07.2019 18:10, Tyrant4life

Draw the engineering stress-strain curve for (a) bcc; (b) fcc metals and mark important points.

Answers: 1

Engineering, 04.07.2019 19:10, pjgolden04

How to increase the thermal officiency of an ideal simple rankino cycle? among these methods, which one is the best and why?

Answers: 2

Do you know the correct answer?

A structural component in the shape of a flat plate 25.0 mm thick is to be fabricated from a metal a...

Questions in other subjects:

Chemistry, 11.10.2019 20:00

English, 11.10.2019 20:00

Mathematics, 11.10.2019 20:00

Geography, 11.10.2019 20:00