Engineering, 17.03.2020 01:17, noahwaitsowl357

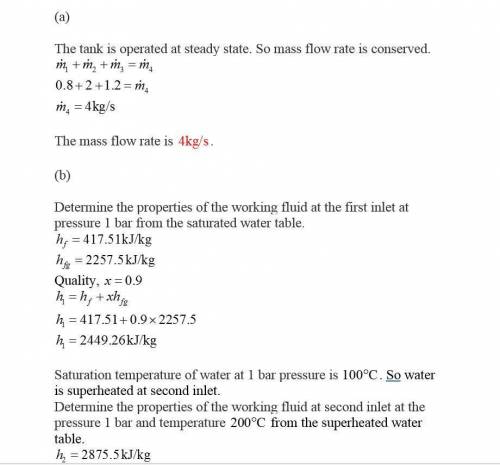

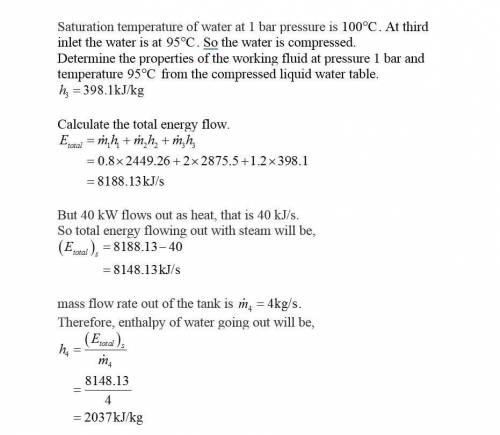

Three return steam lines in a chemical processing plant enter a collection tank operating at steady state at 1 bar. Steam enters inlet 1 with flow rate of 0.8 kg/s and a quality of 0.9. Steam enters inlet 2 with flow rate of 2 kg/s at 200 C. Steam enters inlet 3 with flow rate of 1.2 kg/s at 95 C. Steam exits the tank at 1 bar. The rate of heat transfer from the collection tank is 40 kW. Neglecting kinetic and potential engery effects, determine for the steam exiting the tank

(a) the mass flow rate, in kg/s

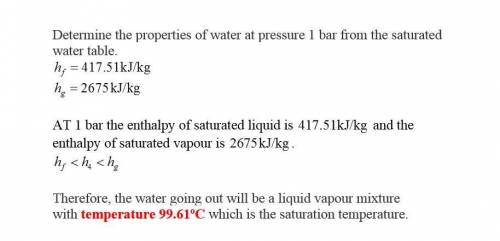

(b) the temperature, in degrees C

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, abdirahmansoloman

Air is to be cooled in the evaporator section of a refrigerator by passing it over a bank of 0.8-cm-outer-diameter and 0.4-m-long tubes inside which the refrigerant is evaporating at -20°c. air approaches the tube bank in the normal direction at 0°c and 1 atm with a mean velocity of 4 m/s. the tubes are arranged in-line with longitudinal and transverse pitches of sl- st 1.5 cm. there are 30 rows in the flow direction with 15 tubes in each row. determine (a) the refrigeration capacity of this system and (b) pressure drop across the tube bank. evaluate the air properties at an assumed mean temperature of -5°c and 1 atm. is this a good assumption?

Answers: 1

Engineering, 04.07.2019 18:10, niyawilliams23

Asingle-geared blanking press has a stroke of 200 mm and a rated capacity of 320 kn. a cam driven ram is assumed to be capable of delivering the full press load at constant force during the last 15 percent of a constant-velocity stroke. the camshaft has an average speed of 90 rev/min and is geared to the flywheel shaft at a 6: 1 ratio. the total work done is to include an allowance of 16 percent for friction a) estimate the maximum energy fluctuation b) find the rim weight for an effective diameter of 1.2 m and a coefficient of speed fluctuation of 0.10

Answers: 1

Engineering, 04.07.2019 18:10, alyssabailey7545

Give heat transfer applications for the following, (i) gas turbines (propulsion) ) gas turbines (power generation). (iii) steam turbines. (iv) combined heat and power (chp). (v) automotive engines

Answers: 1

Do you know the correct answer?

Three return steam lines in a chemical processing plant enter a collection tank operating at steady...

Questions in other subjects:

Mathematics, 29.03.2021 14:50

Physics, 29.03.2021 14:50

Mathematics, 29.03.2021 14:50

Chemistry, 29.03.2021 14:50

Mathematics, 29.03.2021 14:50

Biology, 29.03.2021 14:50