Engineering, 13.03.2020 18:18, police76

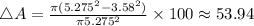

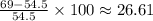

A cylindrical metal specimen having an original diameter of 10.55 mm and gauge length of 54.5 mm is pulled in tension until fracture occurs. The diameter at the point of fracture is 7.16 mm, and the fractured gauge length is 69.0 mm. Calculate the ductility in terms of (a) percent reduction in area (percent RA), and (b) percent elongation (percent EL).

Answers: 1

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, ahmedeldyame

Aloaded platform of total mass 500 kg is supported by a dashpot and by a set of springs of effective stiffness 72 kn/m. it is observed that when the platform is depressed through a distance x = 12.5 cm below its equilibrium position and then released without any initial velocity; it reaches its equilibrium position in the shortest possible time without overshoot. find the position and velocity of the loaded platform 0.10 sec. after its release. if a further load of 400 kg is added to the platform, find, i) the frequency of damped vibrations, and i) the amplitude of vibration after 2 complete oscillations, given that the initial amplitude is 15 cm.

Answers: 1

Engineering, 04.07.2019 18:10, meganwintergirl

Afour cylinder four-stroke in-line engine has a stroke of 160mm, connecting rod length of 150mm, a reciprocating mass of 3kg and its firing order is 1-3-4-2. the spacing between cylinders is 100mm. i. show that the engine is in balance with regard to the primary inertia forces and primary 3. a and secondary inertia couples. li determine the out of balance secondary inertia force ii. propose ways of balancing this out of balance force and discuss the challenges that will arise

Answers: 3

Engineering, 04.07.2019 18:10, kevin72836

Consider a large isothermal enclosure that is maintained at a uniform temperature of 2000 k. calculate the emissive power of the radiation that emerges from a small aperture on the enclosure surface. what is the wavelength ? , below which 10% of the emission is concentrated? what is the wavelength ? 2 above which 10% of the emission is concentrated? determine the wavelength at which maximum spectral emissive power occurs. what is the irradiation incident on a small object placed inside the enclosure?

Answers: 2

Engineering, 04.07.2019 18:10, agpraga23ovv65c

Carbon dioxide gas expands isotherm a turbine from 1 mpa, 500 k at 200 kpa. assuming the ideal gas model and neglecting the kinetic and potential energies, determine the change in entropy, heat transfer and work for each kilogram of co2.

Answers: 2

Do you know the correct answer?

A cylindrical metal specimen having an original diameter of 10.55 mm and gauge length of 54.5 mm is...

Questions in other subjects:

Chemistry, 07.07.2019 00:30

Biology, 07.07.2019 00:30

Mathematics, 07.07.2019 00:30

History, 07.07.2019 00:30

Mathematics, 07.07.2019 00:30

Social Studies, 07.07.2019 00:30

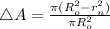

where

where  represent change in area R is radius and subscripts O and n represent original and new respectively.

represent change in area R is radius and subscripts O and n represent original and new respectively.