Engineering, 21.02.2020 04:34, kylaprather06

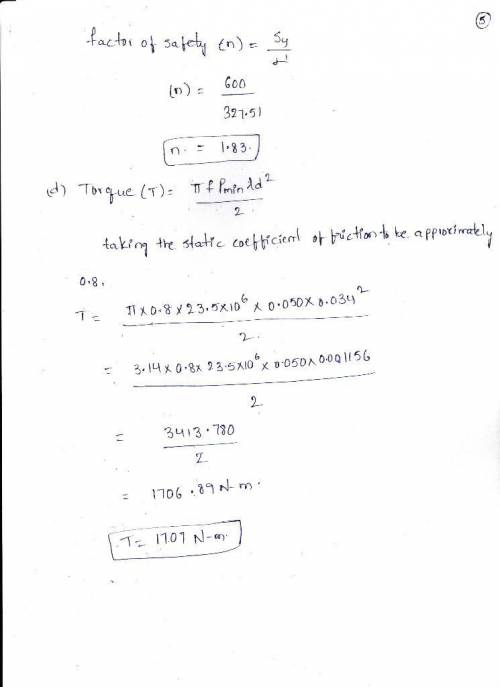

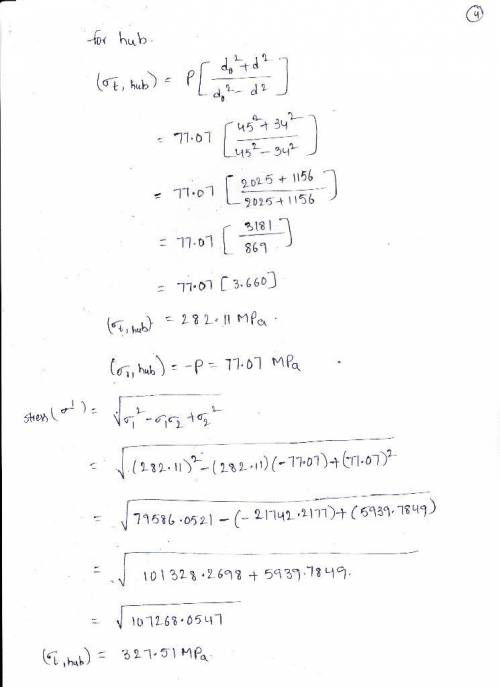

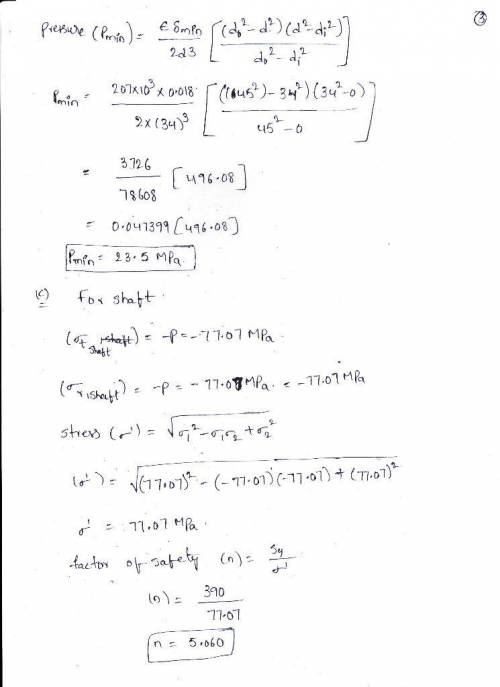

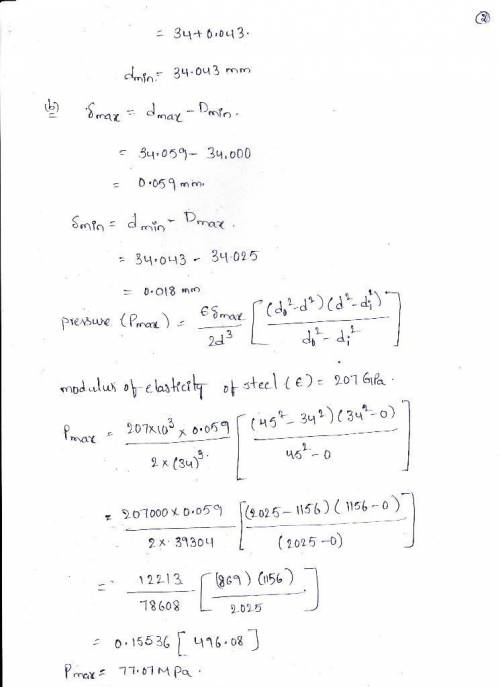

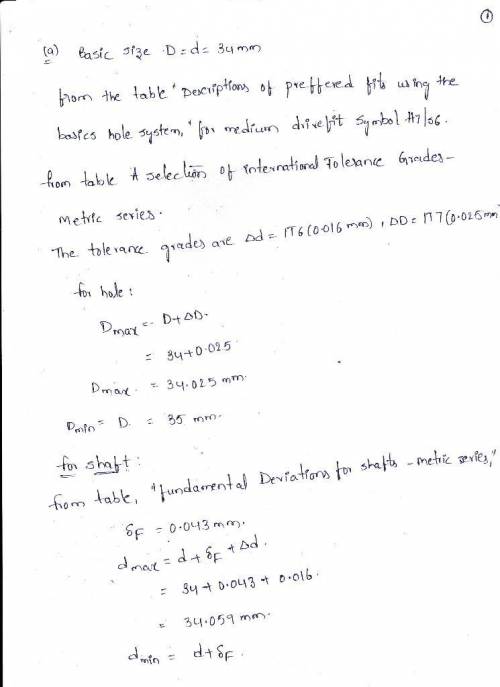

A gear and shaft with nominal diameter of 34 mm are to be assembled with a medium drive fit (H7/s6). The gear has a hub, with an outside diameter of 45 mm, and an overall length of 50 mm. The shaft is made from AISI 1020 CD steel, and the gear is made from steel that has been through hardened to provide Su = 700 MPa and Sy = 600 MPa. a) Specify dimensions with tolerances for the shaft and gear bore to achieve the desired fit. b) Determine the minimum and maximum pressures that could be experienced at the interfaces with the specified tolerances. c) Determine the worst-case static factors of safety guarding against yielding at assembly for the shaft and the gear based on Von-Mises failure theory. d) Determine the maximum torque that the joint should be expected to transmit without slipping.

Answers: 3

Other questions on the subject: Engineering

Engineering, 03.07.2019 14:10, cowgyrlup124

Explain the difference laminar and turbulent flow. explain it with the shear stress and the velocity profiles.

Answers: 1

Engineering, 03.07.2019 15:10, margaret1758

If you were designing a bumper for a car, would you prefer it to exhibit elastic or plastic deformation? why? consider the functions of a bumper in both a minor "fender-bender" and a major collision.

Answers: 1

Engineering, 04.07.2019 18:10, viicborella

Steel is coated with a thin layer of ceramic to protect against corrosion. what do you expect to happen to the coating when the temperature of the steel is increased significantly? explain.

Answers: 1

Engineering, 04.07.2019 18:10, ashleybaber4966

If a particle moves along a path such that r : (3 sin t) m and ? : 2t rad, where t is in seconds. what is the particle's acceleration in m/s in 4 seconds? a)- 16.43 b)- 16.29 c)- 15.21 d)- 13.79

Answers: 1

Do you know the correct answer?

A gear and shaft with nominal diameter of 34 mm are to be assembled with a medium drive fit (H7/s6)....

Questions in other subjects:

History, 25.07.2019 12:00

History, 25.07.2019 12:00

History, 25.07.2019 12:00

English, 25.07.2019 12:00